Authors: Rajesh Bhaskaran & Michael Mahoney, Cornell University

Problem Specification

1. Pre-Analysis & Start-Up

2. Geometry

3. Mesh

4. Physics Setup

5. Numerical Solution

6. Numerical Results

7. Verification & Validation

Exercises

Comments

Verification & Validation

We do not have experimental data to validate our results. So we'll be carrying out only verification here.

Comparison with Hand Calculations

We'll check the following using hand calculations:

Reaction in axial (z) direction where mid nozzle is attached to top nozzle (not modeled)

Thermal strain

Hoop stress

Bolt preload

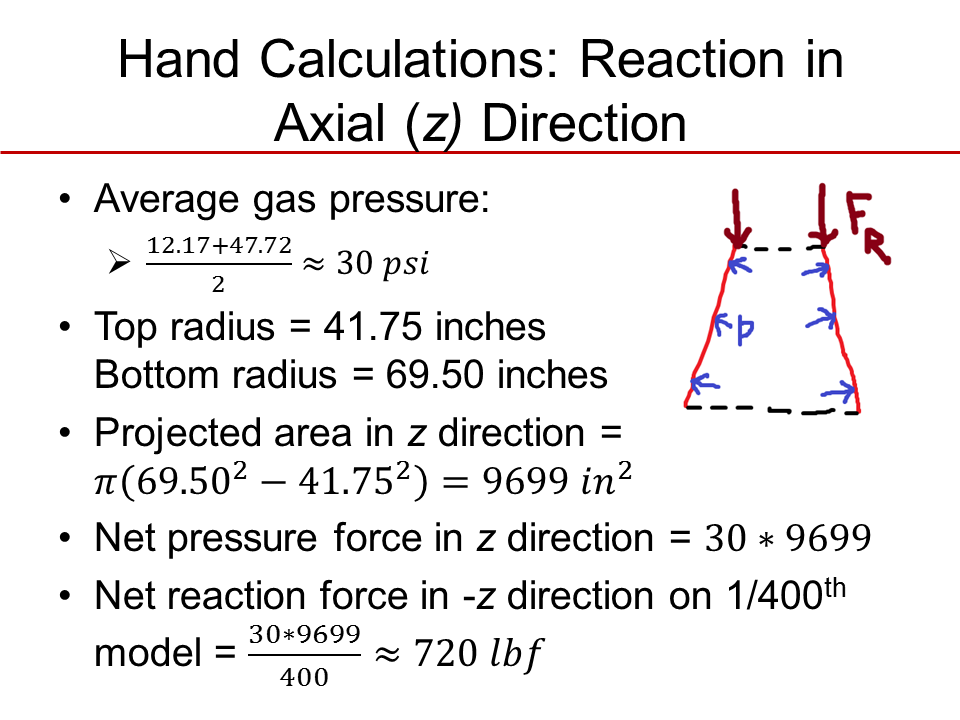

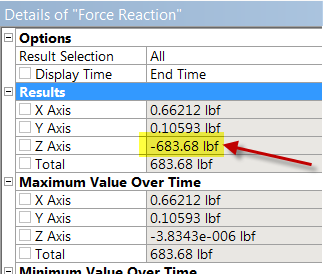

Reaction in Axial Direction

The reaction reported by ANSYS is within 10% of the hand calculation as per the images below.

Thermal Strain

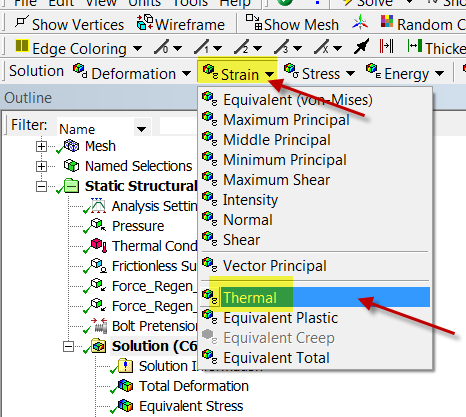

Select Solution > Strain > Thermal

Check that the thermal strain reported by ANSYS for all parts compares well with the expected value from alpha*(dT).

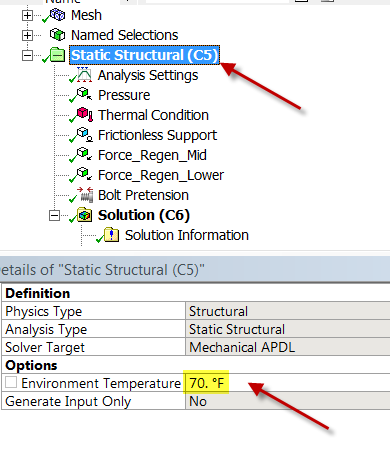

dT is calculated as T2-T1

T2 is the temperature specified in the Thermal Condition under Static Structural. Note that alpha is calculated at this temperature.

T1 is the Environment Temperature. Make sure it is set to 70F as per below.

Hoop Stress

The hoop stress can be estimated using pr/t. Check this against the corresponding ANSYS result which can be determined by looking at the stress in a direction normal to the symmetry planes. You can spot check at a couple of locations in the model.

Bolt Preload

Dragging the Bolt Pretension object under Static Structural to Solution and evaluating results gives the amount by which the bolt has to be shrunk in order to generate the specified preload. See below. The value reported by ANSYS (3.093e-3 in) can be checked using 1D elasticity approximation: dL = (F L)/(E A)

Hex Mesh

The disadvantage of the Hex Dominant meshing technique is that it generates poor elements in transition regions between hex and tet elements. A pure hex mesh can be generated by splitting up the model and using the Multizone meshing technique as per below.

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!