Author: Rajesh Bhaskaran & Yong Sheng Khoo, Cornell University

Problem Specification

1. Create Geometry in GAMBIT

2. Mesh Geometry in GAMBIT

3. Specify Boundary Types in GAMBIT

4. Set Up Problem in FLUENT

5. Solve!

6. Analyze Results

7. Refine Mesh

Step 5: Solve!

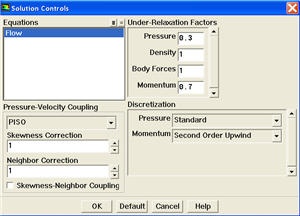

Set Solution Controls

Main Menu > Solve > Controls > Solution...

Select PISO from the Pressure-Velocity Coupling drop-down list.

PISO allows the use of higher time step size without affecting the stability of the solution. Hence it is recommended pressure-velocity coupling for solving transient applications.

Uncheck Skewnes-Neighbor Coupling.

Select Second Order Upwind from the Momentum drop-down list in the Discretization group box. Click OK to close the Solution Controls panel.

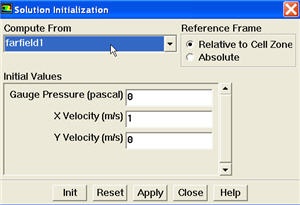

Set Initial Guess

Initialize the flow field to the values at the inlet:

Main Menu > Solve > Initialize > Initialize...

In the Solution Initialization menu that comes up, choose farfield1 under Compute From. The X Velocity for all cells will be set to 1 m/s, the Y Velocity to 0 m/s and the Gauge Pressure to 0 Pa. These values have been taken from the farfield1 boundary condition.

Click Init. This completes the initialization. Close the window.

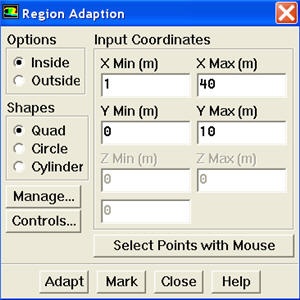

Patch Region

We will patch the upper region downstream of the flow to create asymmetry so that we can obtain stable oscillation of vortex shedding faster.

To do this, we will create a register to patch the Y velocity in downstream of cylinder.

Main Menu > Adapt > Region...

Enter 1 and 40 for X Min and X Max. Enter 0 and 10 for Y Min and Y Max. Click Mark. FLUENT will print the following message in the console window:

5416 cells marked for refinement, 0 cells marked for coarsening

Close the Region Adaption panel.

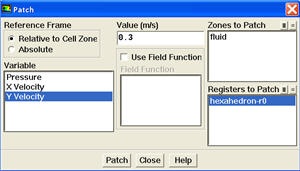

We will now patch Y velocity in the registered region.

Main Menu > Solve > Initializate > Patch...

Select hexahedron-r0 from the Registers to Patch. Select Y Velocity from the Variable selection list. Enter 0.3 for Value. Click Patch.

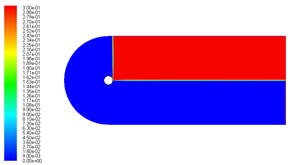

To check whether you have patch the region, plot contour of velocity in the y direction.

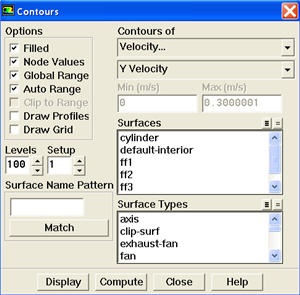

Main Menu > Display > Contours...

Select Velocity... and Y Velocity under Contours of drop-down list. Make sure to check the Filled under Options. Click Display.

As can be seen, the Y Velocity is zero everywhere except for the patched region, we have Y Velocity of 0.3 m/s.

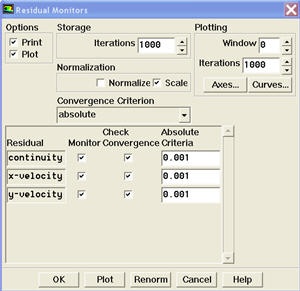

Set Convergence Criteria

FLUENT reports a residual for each governing equation being solved. The residual is a measure of how well the current solution satisfies the discrete form of each governing equation. We'll iterate the solution until the residual for each equation falls below 1e-3.

Main Menu > Solve > Monitors > Residual...

Default value for Convergence Criterion for continuity, x-velocity, and y-velocity is 1e-3.

Also, under Options, select Plot and Print. This will plot the residuals in the graphics window as they are calculated.

Click OK.

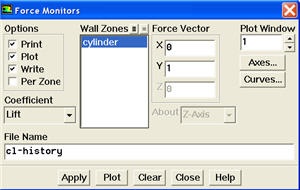

Monitor also the lift coefficient on the cylinder.

Main Menu > Solve > Monitors > Force...

Under Coefficient, select Lift. Select cylinder under Wall Zones. Under Options, select Print, Plot and Write. Note that Plot Window is 1. Click Apply.

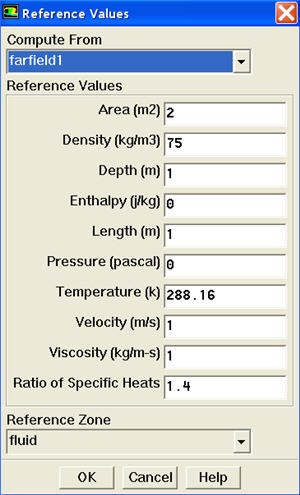

Set Reference Values

The reference values are used to non-dimensionalize the forces and moments action on the wall surface.

Main Menu > Reference Values...

Select ff1 from the Compute From drop-down list. FLUENT will update the reference values based on the boundary conditions at ff1. Change Area to 2. Click OK.

Note that cross sectional area for a 2D cylinder is the diameter of the cylinder.

Iterate the Solution

Main Menu > Solve > Iterate...

You will have to input the time step size for iteration. Smaller time step means more accurate result but more computational time. We need to find the balance between accuracy and computational time.

Calculating Time Step Size

The Strouhal number for flow past cylinder is roughly 0.183 as reported by Williamson (link).

In order to capture the shedding correctly, we should have at least 20 to 25 time steps in one shedding cycle. Let's use 25 for our case.

\large

$$

{\rm{Sr}} =

= 0.183

$$

For our case, D = 2, U = 1

Therefore, shedding frequency f = 0.0915

Cycle time,

\large

$$

{\rm{t}} =

= 10.9 sec

$$

Therefore, Time Step Size = 10.9/25 = 0.436 sec

Enter 0.436 for Time Step Size (s). Enter 30 for Max. Iterrations per Time Step. Enter 600 for Number of Time Steps. Click Apply. Click Iterate to start the iterations.

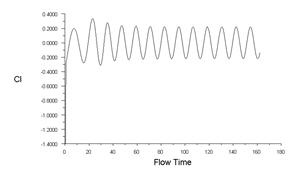

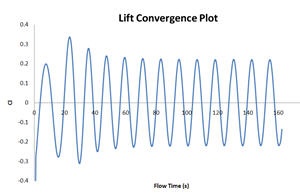

We can see a clear sinusoidal pattern, a sign of sustained vortex shedding process after 40s.This plot can be used to compute the correct value of Strouhal number. The problem is non-dimensionalized (D = 2, U = 1) and Sr = f*D/U = 0.0846 * 2 = 0.169. The results matches fairly well with the value (0.183) as reported by Williamson (link)

Calculating Shedding Frequency

To accurately calculate the shedding frequency, open the cl-history file (saved previously in the same location where the original mesh was read) and plot the data using excel for better data representation and graphing option. Take an average of 10 shedding cycles (e.g 10 CL peak).

Period = (T2-T1)/10

f = 1/Period

Sr = f*D/U

An example of Lift Convergence Plot plotted using excel is shown below:

Save the case and solution.

Main Menu > File > Write > Case & Data...

Use the default name (Mesh's file name "cylinder") and click OK.

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!