Step 5: Mesh geometry

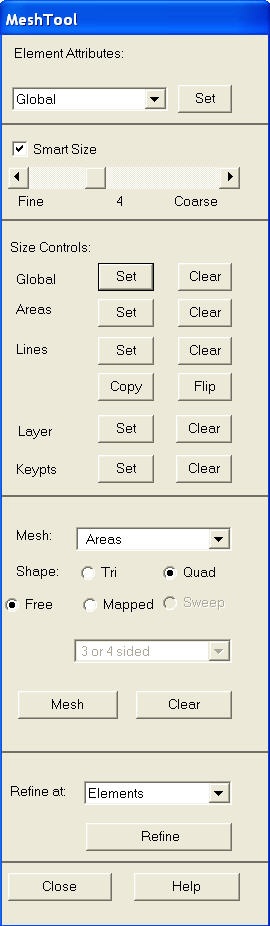

Bring up the MeshTool:

Main Menu > Preprocessor > Meshing > MeshTool

We'll first specify the element type, real constant set and material property set to be used in the meshing. Click Set next to Global under Element Attributes. Make sure that the TYPE is MESH200 and click OK.

According to the ANSYS manual, "Smart element sizing (SmartSizing) is a meshing feature that creates initial element sizes for free meshing operations. SmartSizing gives the mesher a better chance of creating reasonably shaped elements during automatic mesh generation ... The SmartSizing algorithm first computes estimated element edge lengths for all lines in the areas or volumes being meshed. The edge lengths on these lines are then refined for curvature and proximity of features in the geometry." To turn on SmartSizing, check the box next to Smart Size. Drag the slider to a size of 4 to get a finer mesh than the default.

In order to have a little more control over what mesh ANSYS creates for us, we will set the starting element size for SmartSizing rather than use the default. Smartsizing will take this starting element size and modify/vary it over the geometry to account for curvature and corners. Under Size Controls, click the Set button next to Global. Enter an element edge length of 0.12 and click OK.

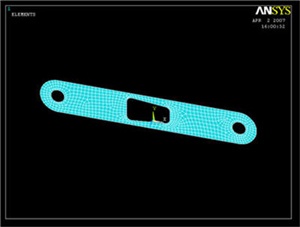

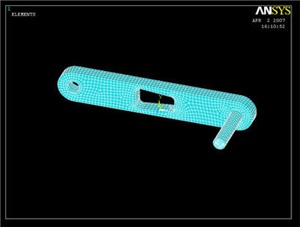

Select Areas to be meshed with a Quad shape using the Free mesher. Click Mesh. Pick the front face of the crank and the pedal shaft. Click OK. You will now see:

The specified smart size 4 and edge length of 0.12 are the result of a iterative process. ANSYS uses a sizing algorithm that creates smaller mesh elements in areas of potentially high stress concentration (e.g. curved regions) to improve solution accuracy. Selecting a smaller (finer) smart size will decrease element size close to the cutout curves. Specifying an edge length provides a uniform size for the rest of the area being meshed. In this case, since the material above and below the cutout act as beams, we want at least two mesh elements in the vertical direction. Feel free to experiment with the mesh tool parameters.

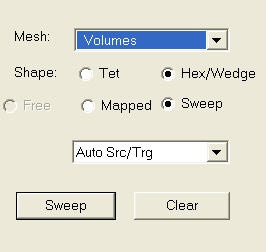

Bring up the MeshTool again, and now Set the mesh type to SOLID45. Under Global Size Controls, click Set. We want four layers of mesh elements to span the thickness of the volume, so we will enter a SIZE Element edge length of (0.5 / 4) = 0.125. Click OK. Since we had created a MESH200 on the face of the crank, we can now simply sweep that mesh across the volume. Choose Volumes with a Shape Hex/Wedge to be meshed. Make sure Auto Src/Trg is selected and click Sweep. Now all we have to do is pick the crank volume, and ANSYS will extend our previous mesh across the volume.

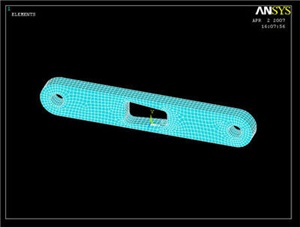

You can always see the rest of your model by selecting Utility Menu > Plot > Volumes

Now repeat the whole procedure with the crank shaft (starting from the top of step 5). Remember that the shaft element size must be the same as the crank so that the shaft elements and crank elements in the hole line up. (You can ignore any errors that may pop up regarding element size. ANSYS is complaining because the shape of some of the quadrilateral elements in high stress areas have a non-ideal element shape) Your final meshed model should look like the following. We're almost ready to solve the problem.

Save Your Work

Toolbar > SAVE_DB

Go to Step 6: Specify boundary conditions

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!