...

| Excerpt |

|---|

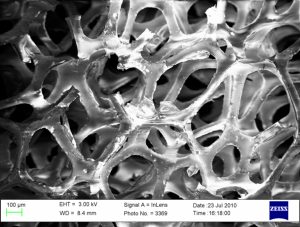

Numerous techniques of water filtration are in use today, most of which involve the use of sand as the porous media. Foam filtration, however, goes beyond traditional water treatment methods and utilizes the filtering capacity of reticulated polyurethane foam. A foam filter requires less surface area, treats higher turbidity water (lab results have shown pC* values of 2 1.5 for 1000 100 NTU influent), wastes less water during backwash, and is less expensive to build than a traditional rapid sand filter. The primary goal of foam filtration is to design a low cost, locally sourced, easy to operate water filtration system for communities of less than 1,000 inhabitants and for disaster-relief scenarios where the community's main water supply has been compromised. |

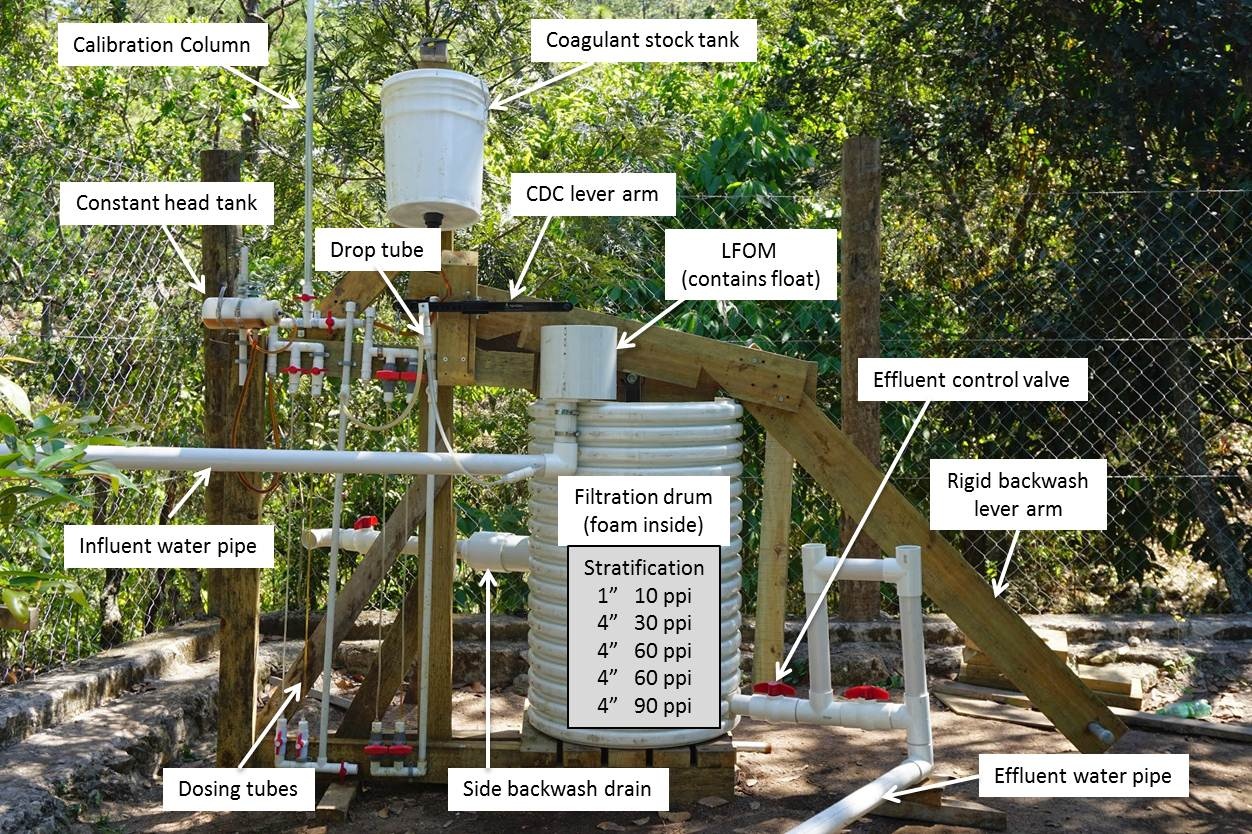

Figure 1: Large filter experimental setup Full scale filter deployed in El Carpintero, Honduras during January 2015

Figure 2: Current Sketch of the current implementation of the Small 4” Pipe Filter in the AguaClara Lab

Figure 3: Example of reticulated foam used in the foam filtration technology

...

Flow through the Filter: Turbid raw water is dosed with coagulant before moving through an inverted linear flow orifice meter and pouring into the top of the foam filter body. As the water passes through all the foam layers, large particles created during flocculation stick to the pores of the foam, removing them from the water and generating a clean, drinkable effluent. When the filter becomes clogged with large flocs, it must be cleaned by initiating the backwash cycle. The backwash system employs a wooden lever-arm to lift the foam and plunge it through water accumulated in the 55 gallon drum24" PVC pipe. This "plunge" creates a high velocity in the pores of the foam, shearing dislodging the captured particles off of from the pore wallsspaces. The backwash water, which comes out the top of the foam layers, is then drained away, and the filtering cycle may resume.

Current & Future Research

Spring 2015

Throughout the semester, backwash cleaning efficiency experiments were performed on the small-scale filter, designed in Fall 2014 to hydraulically model the full scale filter implemented in El Carpintero. The objective of these experiments was to determine an empirical relationship between backwash pore velocity and the percent mass removal of the particles from the foam during the cleaning cycle. Experimentation with different pore sizes revealed a new mechanism for filtration: the foam acts as a sedimentation tank, providing a large surface area for the flocs to settle. This is contrary to the initial hypothesis that coagulant-covered flocs stuck to the inside of the pore walls, and that a large shear force would be required to remove the flocs during backwash. Evidently, there is still much to be understood with regards to the mechanisms behind filtration and backwash.

Apart from work in the laboratory, the team continues to analyze data collected from experiments performed on the full-scale filter in El Carpintero by AguaClara engineer, Walker Grimshaw, to understand the discrepancies between performance in the laboratory and in the field.

Much of the semester was spent preparing for the EPA P3 Conference held on April 10th and 11th in Washington, DC. The team fabricated a small scale model of the technology, prepared a technical report, and created a poster display for the competition, and received an Honorable Mention for its efforts in creating an “Off-Grid Solution to Drinking Water Treatment.”

Fall 2014

The Fall 2014 Foam Filtration team has focused its efforts in exploring the new backwashing method with the design and construction of a new apparatus: the 4” Pipe Small Scale Filter. Experiments performed on this filter, designed to hydraulically model the full scale filter, will be used to determine an empirical relationship between backwash pore velocity and the percent mass removal of the particles from the foam during the cleaning cycle.

...

| Section | ||||||

|---|---|---|---|---|---|---|

|