Foam Filtration

Currently, an AguaClara plant can produce effluent water after sedimentation with a turbidity of about 5 NTU. Our goal is to reduce the effluent turbidity to less than 1 NTU. One potential method of accomplishing this is adding a filtration unit to the AguaClara plants.

| Excerpt |

|---|

Numerous techniques of water filtration are in use today, most of which involve the use of sand as the porous media. |

...

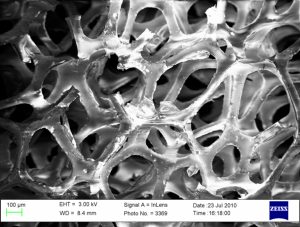

Foam filtration, however, goes beyond traditional water treatment methods and utilizes the filtering capacity of reticulated polyurethane foam. A foam filter requires less surface area, treats higher turbidity water (lab results have shown pC* values of 1.5 for 100 NTU influent), wastes less water during backwash, and is less expensive to build than a traditional rapid sand filter. |

...

The primary goal of foam filtration is to design a low cost, locally sourced, easy to operate water filtration system for communities of less than 1,000 inhabitants and for disaster-relief scenarios where the community's main water supply has been compromised. |

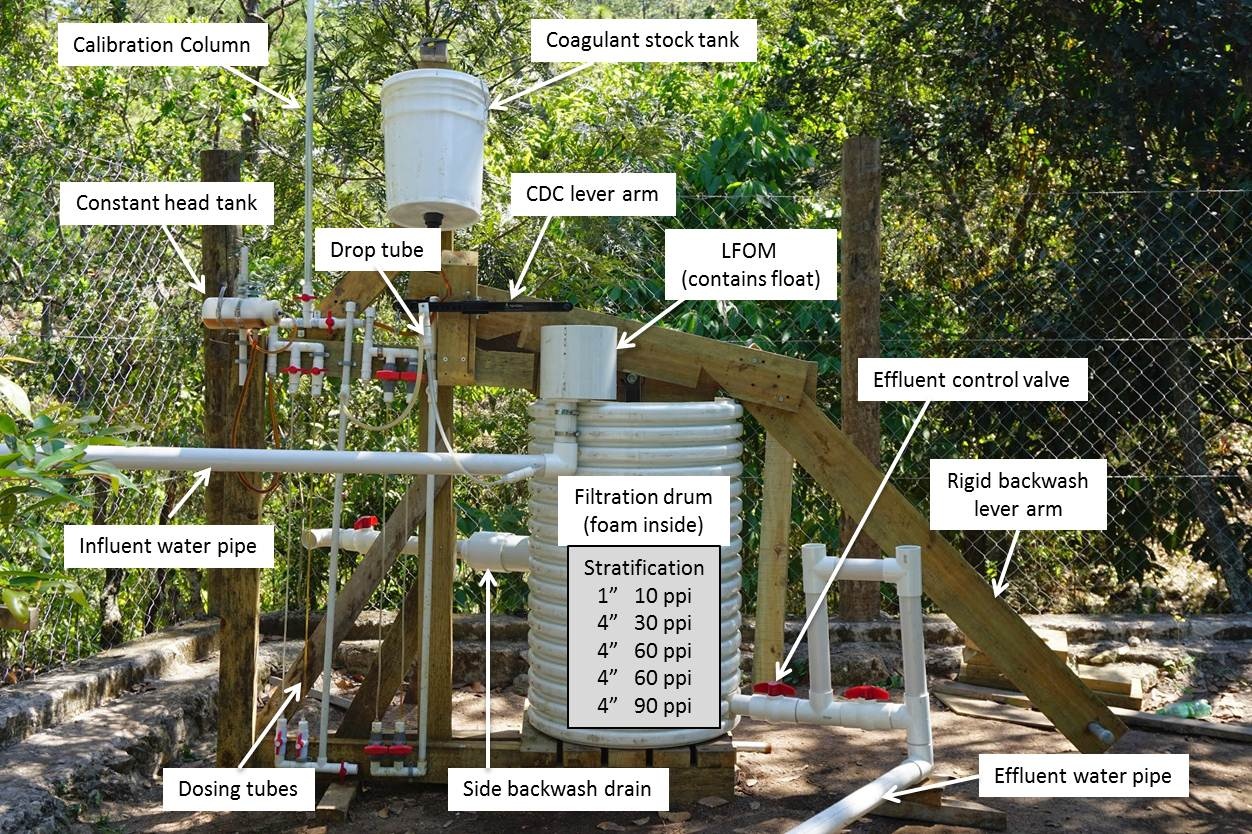

Figure 1: Full scale filter deployed in El Carpintero, Honduras during January 2015

Figure 2: Sketch of the current implementation of the Small 4” Pipe Filter in the AguaClara Lab

Figure 3: Example of reticulated foam used in the foam filtration technology

Flow through the Filter: Turbid raw water is dosed with coagulant before moving through an inverted linear flow orifice meter and pouring into the top of the foam filter body. As the water passes through all the foam layers, large particles created during flocculation stick to the pores of the foam, removing them from the water and generating a clean, drinkable effluent. When the filter becomes clogged with large flocs, it must be cleaned by initiating the backwash cycle. The backwash system employs a wooden lever-arm to lift the foam and plunge it through water accumulated in the 24" PVC pipe. This "plunge" creates a high velocity in the pores of the foam, dislodging the captured particles from the pore spaces. The backwash water, which comes out the top of the foam layers, is then drained away, and the filtering cycle may resume.

Spring 2015

Throughout the semester, backwash cleaning efficiency experiments were performed on the small-scale filter, designed in Fall 2014 to hydraulically model the full scale filter implemented in El Carpintero. The objective of these experiments was to determine an empirical relationship between backwash pore velocity and the percent mass removal of the particles from the foam during the cleaning cycle. Experimentation with different pore sizes revealed a new mechanism for filtration: the foam acts as a sedimentation tank, providing a large surface area for the flocs to settle. This is contrary to the initial hypothesis that coagulant-covered flocs stuck to the inside of the pore walls, and that a large shear force would be required to remove the flocs during backwash. Evidently, there is still much to be understood with regards to the mechanisms behind filtration and backwash.

Apart from work in the laboratory, the team continues to analyze data collected from experiments performed on the full-scale filter in El Carpintero by AguaClara engineer, Walker Grimshaw, to understand the discrepancies between performance in the laboratory and in the field.

Much of the semester was spent preparing for the EPA P3 Conference held on April 10th and 11th in Washington, DC. The team fabricated a small scale model of the technology, prepared a technical report, and created a poster display for the competition, and received an Honorable Mention for its efforts in creating an “Off-Grid Solution to Drinking Water Treatment.”

Fall 2014

The Fall 2014 Foam Filtration team has focused its efforts in exploring the new backwashing method with the design and construction of a new apparatus: the 4” Pipe Small Scale Filter. Experiments performed on this filter, designed to hydraulically model the full scale filter, will be used to determine an empirical relationship between backwash pore velocity and the percent mass removal of the particles from the foam during the cleaning cycle.

The Chemical Dose Controller was redesigned with (1) an altered constant head tank constructed from Nalgene bottles or a 3” pipe, (2) the float situated inside the LFOM, eliminating the need for an entrance tank, and (3) major headloss elements that run vertically to reduce overall size.

Tests through mass spectrometry have confirmed that chemicals are leaching from the foam, however more testing must be done to determine the composition of the leachate. Designs for the on-the-ground implementation of the foam filter pilot project have been drawn up by AguaClara Engineer, Walker Grimshaw in Honduras. This design includes the set-up for the chemical stock tanks, designs for managing backwash and finished water, and the possible addition of a grit chamber.

The lever arm used for plunging the foam was redesigned with a rigid connection to the base of the filter support. This rigid connection eliminates large movement in the z-direction and the need for guidance by the barrel lid on the 55-gallon drum. The open-top design allows for integration of the new CDC/LFOM design: influent raw water pours out of the LFOM and directly into the filter body.

Read more about what the foam filtration team hopes to accomplish through Future Research.

| Section | ||||||

|---|---|---|---|---|---|---|

|

With these advantages and cautions in mind, we have considered a number of different designs which could provide the desired standard of 1 NTU effluent water turbidity.

Keep updated with Reflection Reports and Future Challenges

Foam Filtration Current Research

Team Members - Summer 2010

High Velocity Polyurethane Foam Filter Performance Study

Since laboratory research has shown that horizontal flow foam filtration is not a feasible method for achieving the desired filtration performance, it is necessary to manipulate the geometry of the proposed foam filtration unit in another way. With a high velocity foam filter, the depth of the foam will be increased to accommodate the increased velocity. With an increased filtration velocity, the filtration unit will require less planned area, which reduces the associated construction and maintenance costs.

We would like to analyze the impact of the variation of parameters within our foam filtration experiment in order to determine the optimal set of parameters to design a filtration unit for, and the range conditions which the filter will be effective for. The parameters we will study are filter depth, filtration downflow velocity, influent turbidity, and presence the of an alum dose.

Foam Filtration Past Research

Foam Filtration Future Research

After laboratory tests on the filtering capacity of the polyurethane foam material are concluded, the following areas of research will be explored:

Head Loss Calculation

The amount of headloss that occurs with the build up of particles in the foam will determine how often the filter will require cleaning, and the additional height required for the walls of the filtration unit to accomodate this additional head loss. It is therefore important to measure the change in headloss over the running time of the filter.

Aluminum Hydroxide Wash

Research has shown that the foam material has a fairly long ripening time. In order to reduce this ripening time, it may be useful to prime the filter with an aluminum hydroxide rinse after cleaning. This may reduce the time delay in the filter becoming coated with enough alum to achieve the desired filtration performance. In this test, we will need to determine whether the aluminum hydroxide will result in excess aluminum being washed into the effluent water from the filter. It will then be necessary to determine a washing and foam reinstallation method to reduce this effect.

Effect of Natural Organic Matter

If we conclude from laboratory tests that the foam material provides adequate filtration, it will be necessary to test the effects of natural organic matter on the foam material.

Foam Filtration Unit Design

This filtration unit design should be optimized according to the required surface area and filtration velocity parameters determined through previous laboratory experiments. In addition, it should minimize the required plan area, as well as maximize the ease of maintenance for the operator.

Cleaning Method

After determining the effects of natural organic matter on the foam material, we will propose a standardized method for cleaning and replacing the foam.

Foam Media Upflow Design

An alternative to using the foam simply as a flat sheet which water is filtered through is to design a hybrid upflow filter, which uses small pieces of the foam as the filtering material, as opposed to the traditional upflow sand filter. This idea is based on the technique outlined in this article, Water Filtration- Advantages of Fabric Media