| Include Page | ||||

|---|---|---|---|---|

|

Step 1: Pre-Analysis & Start-Up

With From the current problem setupstatement, we know that the temperature will increase as the air passing through the heated section. Depending on whether the pipe is long enough, we might see uniform temperature at the end of the pipe.Since the pipe cross-section is circular, we 'll assume that the flow is axisymmetric. In cylindrical polar coordinates, this means that the flow variables depend only on the axial coordinate x and radial coordinate r, and are independent of the azimuthal coordinate θ. Hence we can model the pipe problem with a rectangular domain.

Figure above shows the simplified geometry of our problem where R = radius of the pipe, and L = length of the pipe.

ANSYS Simulation Flow

are solving static structural problem.

Start ANSYS Workbench

We are using FLUENT in solving this problem. With the new release of ANSYS 12, there have been a lot of improvement in term of overall flow. We start our simulation by first starting the ANSYS workbench.

...

At the left hand side of the workbench window, you will see a toolbox full of various analysis systems. In the middle, you see an empty work space. This is the place where you will organize your project. At the bottom of the window, you see messages from ANSYS.

Select Analysis Systems

| newwindow | ||||

|---|---|---|---|---|

| ||||

https://confluence.cornell.edu/download/attachments/111234447/Select%20Analysis%20System.gif

|

Since our problem involves fluid flowstatic analysis, we will select the FLUENT Static Structural (ANSYS) component on the left panel.

Left click (and hold) on Fluid Flow Static Structural (FLUENTANSYS), and drag the icon to the empty space in the Project Schematic. Here's what you get:

...

...

https://confluence.cornell.edu/download/attachments/111221567/workbench%20fluent.pngSince we selected Fluid Flow Static Structural (FLUENTANSYS), each cell of the system corresponds to a step in the process of performing the FLUENT ANSYS Structural analysis. Rename the project to Forced Convection Crank.

Now, we just need to work out each step from top down to get to the results for our solution.

- We start by preparing our geometry

- We use geometry to generate a mesh

- We setup the physics of the problem

- We run the problem in the solver to generate a solution

- Finally, we post process the solution to gain insight into the results

Specify Material Properties

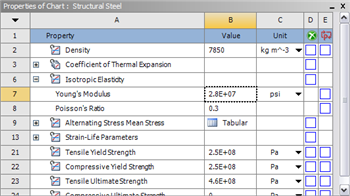

We will first specify the material properties of the crank. The material has an Young's modulus E=2.8x107 psi and Poisson's ratio ν=0.3.

In the Crank cell, double click on Engineering Data. This will bring you to a new page. The default material given is Structural Steel. We will use this material and change the Young's modulus and Poisson's ratio.

Left click on Structural Steel once and you will see the details of Structural Steel material properties under Properties of Outline Row 3: Structural Steel. Under Isotropic Elasticity, change Young's Modulus and Poisson's Ratio to E=2.8e7 psi and ν=0.3. Remember to change the unit accordingly.

| newwindow | ||||

|---|---|---|---|---|

| ||||

https://confluence.cornell.edu/download/attachments/111234447/Material%20Properties.png

|

Press the Return to Project to return to Workbench Project Schematic window.

See and rate the complete Learning Module

Go to all FLUENT ANSYS Learning Modules

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!