Cuatro Communidades Flocculator

Abstract

The flocculator at the Cuatro Communidades plant uses a vertical set of baffles to mix alum with contaminants in the raw water. The Cuatro Communidades flocculator has three channels. The baffles are arranged in a tapered configuration so that flocs are exposed to higher energy dissipation rates initially and lower rates as they grow. In this study, tube settlers were used to measure residual turbidity at different points along the flocculator. Tube settlers were placed along the flocculator to determine how much flocculation was occurring in the last flocculator channel. The results were compared at different raw water turbidities.

Introduction and Objectives

During flocculation alum is mixed with raw water and in the process aggregates of contaminants called flocs are formed. Flocs settle out of water more easily than the contaminants themselves because they are heavier. Alum is a coagulant used to help floc formation. Conventional flocculators typically use a long slow mechanical stirring process to mix alum and contaminants together. This long process slowly builds large flocs. To avoid the use of electricity, flocculation occurs as water snakes through a vertical set of baffles. The energy dissipation rate through these baffles is set by the distance between the baffles. This rate is a measure of how much mixing is occurring.

The Cuatro Communidades plant has a tapered set of baffles. The baffles are close together and the energy dissipation rates are high early in the flocculator. When the flocs have grown and are more fragile the energy dissipation is lower. It was unclear at what point in the flocculator the flocs were large enough to settle out in the sedimentation tank. Tube settlers were used to measure residual turbidity along the flocculation channels. Tube settlers were placed at different locations in the flocculator to determine if adequate flocculation had occurred before the end of the flocculator and if the last channel in the flocculator was improving residual turbidity.

Methods

Each tube settler functioned in as an isolated pair of lamella in the sedimentation tanks. In order to mimic the design of the lamella in the Cuatro Communidades plant the tube settlers were designed to rest at a sixty degree angle, alpha, and with a critical velocity, V alpha, of 10 m/day. The critical velocity of the tube settler determines the size of the smallest floc that is able to settle out in the tube settler.

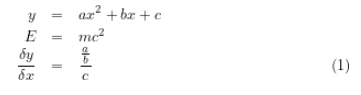

The critical velocity is calculated by the equation:

where:

- V c is the critical velocity

- D is the tube settler diameter

- L is the length of the tube settler

- is sixty degrees

- is the velocity in the tube settler

The tube settlers were designed to siphon water from the flocculator. Water settled out in a PVC pipe and passed into a small flexible tube from which it was collected. The flow rate was controlled by the height difference between the tube settler outlet and the water level in the flocculator using the equation:

where:

- h is the height difference used to control the siphon

- V siphon is the exit velocity of the clear tube

- is the velocity in the tube settler

- h l was the head loss in the entire system

The tube settlers were placed at various locations in the last two flocculator channels and the effluent turbidity from the tube settlers was measured.

The turbidity was measured every thirty minutes at each location and the results were averaged. Results were only considered valid when the raw water turbidity and the alum dose were constant throughout the entire trial. It should be noted that the flow rate was not constant in every trial. This affects the results because decreasing the flow rate decreases the energy dissipation rate through the baffles. A table of flow rates and trials can be seen below.

Table 1

Raw Water Turbidity (NTU) |

Flow Rate (L/min) |

|---|---|

115 |

255 |

72 |

285 |

35 |

255 |

30 |

210 |

Results and Discussion

Residual turbidities were measured at four different incoming turbidities along the flocculator shown in figure 3.

The results are not very comparable as different incoming turbidities were measured at different points along the flocculator and at different flow rates. However, the results show a 1-3 NTU decrease in residual turbidity in the end of the third flocculator channel— between baffles 45 and 59. Flocs must be growing much more slowly here compared to the first two channels where floc growth reduces the residual turbidity more rapidly. Although this final reduction seems small, it is not insignificant. In the case of the 30 NTU raw water turbidity trial— the trial that saw the largest decrease in turbidity in the final channel— the turbidity decreases to 4.5 NTU, sixty percent of the 7.7 NTU that entered the final channel. While the improvements in turbidity in the final channel are small they are still a significant percent of the incoming residual turbidity. It should be noted that the flow rate was much lower in the 30 NTU trial therefore the energy dissipation rate was lower as well. Because of the difference in energy dissipation rates, flocculation was probably occurring later at this low flow rate. This would explain the larger decrease in residual turbidity in the final channel. The flow rate through the plant was variable and it was not uncommon to see plant flow rates as low as 210 L/min. The third flocculator channel was probably more beneficial when the plant flow rate was lower.

A peak in turbidity is seen after baffle 36 in the middle of the second flocculator channel in the 30 NTU raw water turbidity trial. An earlier trial (not shown) indicated this peak might be after baffle 29. This trial is not shown because plant conditions were changing as data was being taken. This peak is due to flocs that large enough to block the light from the turbidimeter but too small to settle out quickly. This peak was not measured in the other three trials. If the location of this peak is of interest more measurements should be taken along the second flocculator channel. The location of this peak would be another way to determine the effects of lower plant flow rates and lower energy dissipation rates on flocculation.

Conclusions

Most floc growth is occurring in the first two channels of the flocculator. There is only a 1-3 NTU decrease in residual turbidity in the third flocculator channel. This decrease is small but still significant on the way to producing water under 1 NTU. The third channel probably has more of an impact on residual turbidity when the plant flow rate is lower.