Step 5: Mesh geometry

Each truss member can be represented as a 2D Spar element. We'll use the MeshTool to mesh the geometry with this element.

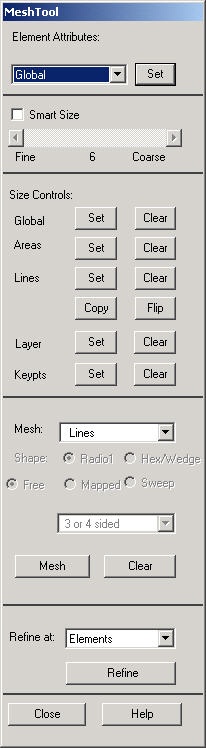

To bring up the MeshTool, select

Main Menu > Preprocessor > Meshing > MeshTool

The MeshTool is used to control and generate the mesh.

Set Meshing Parameters

We'll now specify the element type, real constant set and material property set to be used in the meshing. Since we have only one of each, we can assign them to the entire geometry using the Global option under Element Attributes.

Make sure Global is selected under Element Attributes and click on Set.

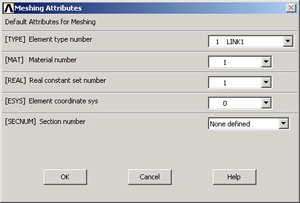

This brings up the Meshing Attributes menu. You will see that the correct element type, material number and real constant set are already selected since we have only one of each.

Click OK. ANSYS now knows what element type (and associated constants) and material type to use for the mesh.

Set Mesh Size

Since a LINK1 element is equivalent to a truss member, we will specify that we want only one element per line. This is a subtle point and also very unusual; in most problems, you want to subdivide your part into many elements.

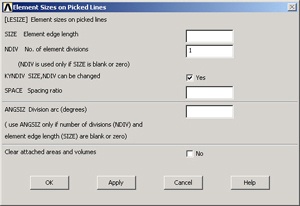

In the MeshTool, under Size Controls and Lines , click Set.

In the pick menu that comes up, click Pick All (since we want the specification of mesh size to apply to all lines in the geometry). This brings up the Element Sizes on Picked Lines menu. Specify No. of element divisions to be 1. Click OK. ANSYS will now use 1 element to mesh each line.

Mesh Lines

In the MeshTool, make sure Lines is selected in the drop-down list next to Mesh. This means the geometry components to be meshed are lines (as opposed to areas or volumes, as we'll see later). Click on the Mesh button.

This brings up the pick menu. Since we want to mesh all lines, click on Pick All. The lines have been meshed. This is reported in the Output Window (usually hiding behind the Graphics Window):

NUMBER OF LINES MESHED = 3

MAXIMUM NODE NUMBER = 3

MAXIMUM ELEMENT NUMBER = 3

Close the MeshTool.

View Element List

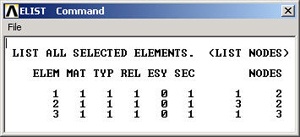

Utility Menu > List > Elements > Nodes + Attributes

This table says that Element 1 is of material type 1 and element type 1 and is attached to nodes 1 and 2 and so on. In this element list, the order of the two nodes for each element doesn't matter. For example, element 3 can be attached to nodes 2 and 3 or equivalently, nodes 3 and 2. Also, the order of element numbering is not important since it is for internal bookkeeping.

Close the window listing the elements.

View Node Location

In order to see where the nodes are located, you can look at the list of nodes.

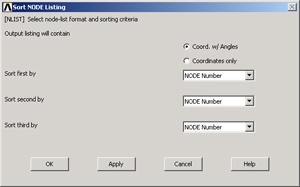

Utility Menu > List > Nodes

In Sort NODE Listing menu, click OK to accept defaults.

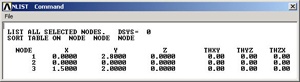

My list of nodes looks like this:

From the node and element lists, one can conclude that in this case:

Node 1 is pin A

Node 2 is pin C

Node 3 is pin B

Element 1 is member AC

Element 2 is member AB

Element 3 is member BC

Your own node and element numbering might be different from this and you would have to account for this while interpreting results in the postprocessing step.

Close the window listing the nodes.

Save your work

Toolbar > SAVE_DB

Go to Step 4: Specify geometry

...

Go to Step 6: Specify boundary conditions

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!