...

- Build a nonlinear finite-element model to analyze a bolted assembly

- Model contacts between parts in an assembly

- Model thermal strains

- Model temperature-dependent material properties

- Verify the finite-element model by refining the mesh and also comparing with hand calculations

| Note |

|---|

Under ConstructionThis module is under construction |

Problem Specification

...

...

Under Construction

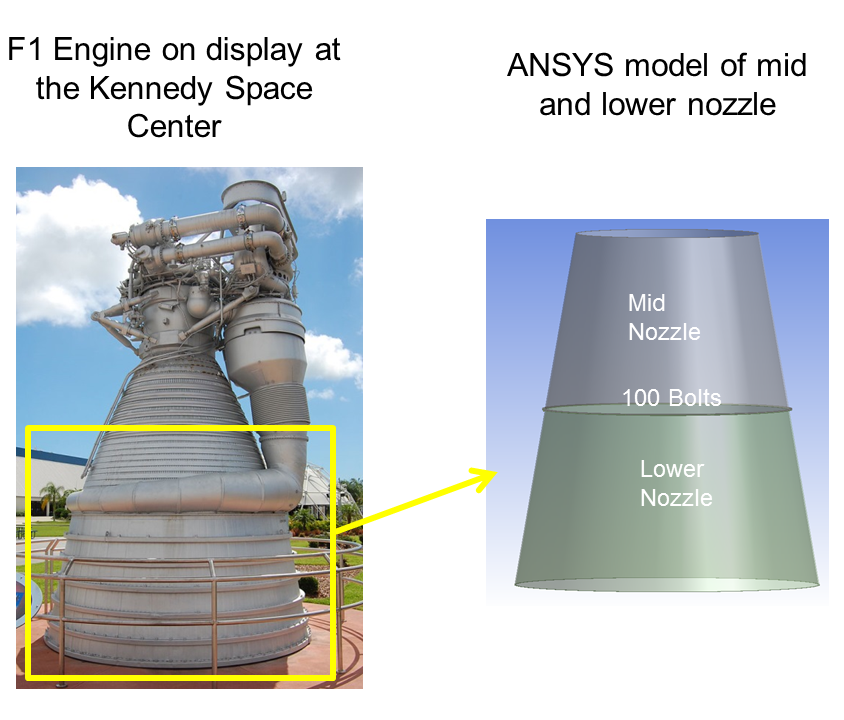

The Saturn V rocket that carried people to the moon is the most powerful machine ever built. Watch this awe-inspiring video to get a sense of the tremendous power packed into this rocket. The Saturn V's first stage was powered by five F1 engines. In this exercise, we analyze the bolted flange joint that connected the mid and lower parts of the nozzle as illustrated in the images belowF1 engine nozzle. The image below show a picture of the F1 engine and the corresponding model of the mid and lower parts of the nozzle in the ANSYS.

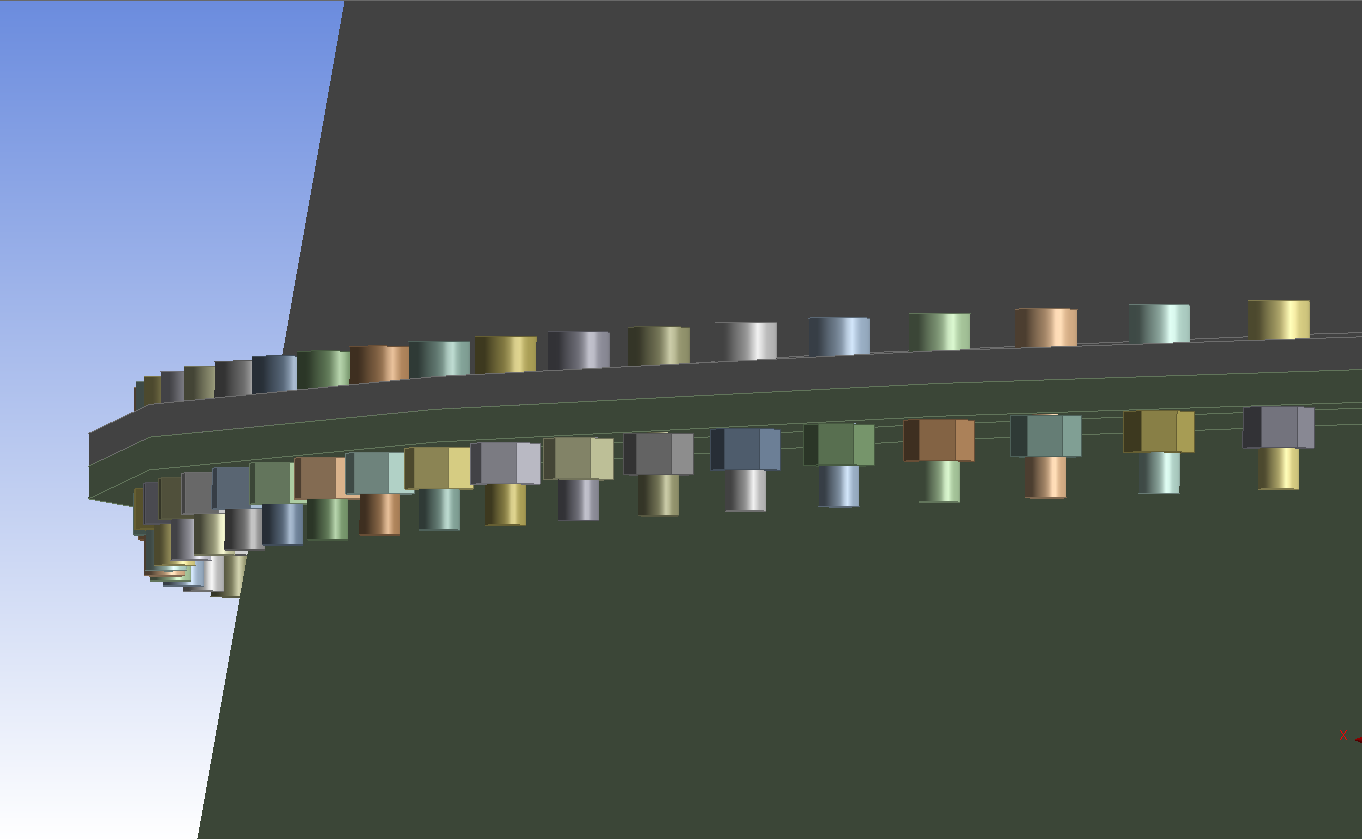

Below is close-up view of the bolted flange joint connecting the mid and lower parts of the nozzle.

We'll build a model of this bolted joint using ANSYS. Our main objective is to assess the margin of safety of the F1 nozzle flange flange bolts. We'd also like to determine the separation between the jointed parts.

Loads

The pressure due to the exhaust gas is calculated using 1D gas dynamics. It is assumed to vary linearly in the axial direction. The pressure values at the top and bottom of our model is shown in the image below. We'll assume a linear variation

The details of the load calculations are provided in this Excel file <<<include link>>>.

Go to Step 1: Pre-Analysis & Start-Up

...

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!