Foam Filtration

| Excerpt |

|---|

Numerous techniques of water filtration are in use today, most of which involve the use of sand as the porous media. Foam filtration, however, goes beyond traditional water treatment methods and utilizes the filtering capacity of reticulated polyurethane foam. A foam filter requires less surface area, treats higher turbidity water (lab results have shown pC* values of 2 for 1000 NTU influent), wastes less water during backwash, and is less expensive to build than a traditional rapid sand filter. The primary goal of foam filtration is to design a low cost, locally sourced, easy to operate water filtration system for communities of less than 1,000 inhabitants and for disaster-relief scenarios where the community's main water supply has been compromised. |

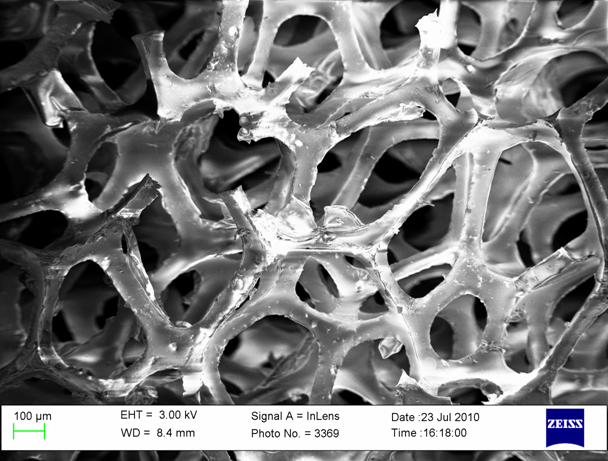

Numerous techniques of water filtration are in use today, most of which involve the use of sand as the porous media. Foam filtration, however, goes beyond traditional water treatment methods and utilizes the filtering capacity of reticulated polyurethane foam. A foam filter requires less surface area, treats higher turbidity water (lab results have shown pC* values of 2 for 1000 NTU influent), wastes less water during backwash, and is less expensive to build than a traditional rapid sand filter. The primary goal of foam filtration is to design a low cost, locally sourced, easy to operate water filtration system for communities of less than 1,000 inhabitants and for disaster-relief scenarios where the community's main water supply has been compromised.

...

The Fall 2014 Foam Filtration team has focused its efforts in exploring the new backwashing method with the design and construction of a new apparatus: the 4” Pipe Small Scale Filter. Experiments performed on this filter, designed to hydraulically model the full scale filter, will be used to determine an empirical relationship between backwash pore velocity and the percent mass removal of the particles from the foam during the cleaning cycle.

...

.

The Chemical Dose Controller was redesigned with (1) an altered constant head tank constructed from Nalgene bottles or a 3” pipe, (2) the float situated inside the LFOM, eliminating the need for an entrance tank, and (3) major headloss elements that run vertically to reduce overall size.

...