Foam _Filtration_Summer_2014.pdfFoam Filtration

Numerous techniques of water filtration are in use today, most of which involve the use of sand as the porous media. A preliminary literature review revealed a dearth of information on foam filtration. Our team has decided to focus on investigating the actual filtering capacity of a polyurethane foam material as opposed to the traditional method of sand filtration. With proper implementation, a foam filter could reduce the amount of water that is wasted during the backwash cycle of a traditional sand filterFoam filtration, however, goes beyond traditional water treatment methods and utilizes the filtering capacity of reticulated polyurethane foam. A foam filter requires less surface area, treats higher turbidity water (lab results have shown pC* values of 2 for 1000 NTU influent), and could potentially be wastes less water during backwash, and is less expensive to build than a traditional rapid sand filter. However, a foam filtration unit will also require a tight seal with all of the edges of the tank, in order to avoid preferential flow paths which will result in unfiltered water. In addition, a foam filter will likely require manual maintenance by the plant operator The primary goal of foam filtration is to design a low cost, locally sourced, easy to operate water filtration system for communities of less than 1,000 inhabitants and for disaster-relief scenarios where the community's main water supply has been compromised.

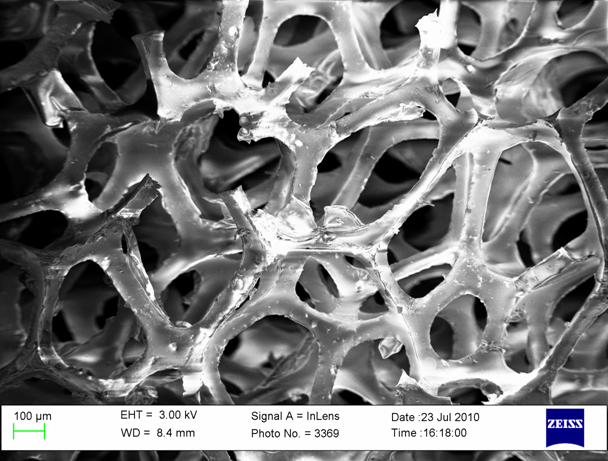

Flow through the Filter: Turbid raw water is dosed with coagulant before moving through an inverted linear flow orifice meter and pouring into the top of the foam filter body. As the water passes through all the foam layers, large particles created during flocculation stick to the pores of the foam, removing them from the water and generating a clean, drinkable effluent. When the filter becomes clogged with large flocs, it must be cleaned by initiating the backwash cycle. The backwash system employs a lever-arm to lift the foam and plunge it through water. This "plunge" creates a high velocity in the pores of the foam, shearing the captured particles off of the pore walls. The backwash water, which comes out the top of the foam layers, is then drained away.

Foam filtration has been ruled out for an AguaClara plant because the foam would be too difficult for an operator to clean. However, previous research has proven that foam is an effective method of filtration, therefore this team decided to focus on designing a point of use foam filtration unit. Due to chemical dosing and usability concerns, the point-of-use application was ruled out as a possibility for foam filtration. The team then focused on the design of an emergency filtration system that can be transported on the back of a pickup truck. After speaking with communities in Honduras, it was decided that foam filtration would be more useful in small communities. Research has been done to optimize the design such that it is as efficient as possible and provides the desired standard of 1 NTU effluent water turbidity.

...

Current & Future Research

After visiting Honduras, the apparatus designed in fall 2013 was implemented with mild success. The design met the desired constraint of 1 NTU however the filter was difficult to use, especially in cleaning. The Fall 2013 team designed the foam filtration unit to fit all into one 55 gallon drum. The apparatus consisted of two 23” disks: a roughing filter that used 30 ppi* foam and a finishing filter with 90 ppi foam. The filter unit was designed on the premise of providing water for a community of 100 families at approximately 1 L/s. The Spring 2014 team updated the apparatus for easy use and transportThe Fall 2014 Foam Filtration team has focused its efforts in exploring the new backwashing method with the design and construction of a new apparatus: the 4” Pipe Small Scale Filter. Experiments performed on this filter, designed to hydraulically model the full scale filter, will be used to determine an empirical relationship between backwash pore velocity and the percent mass removal of the particles from the foam during the cleaning cycle.

| Excerpt |

|---|

In order to clean this unit, a user-friendly simple pulley design with a hoist supporting approximately 500 pounds of concrete was implemented to compress the foam with a hard plastic plunging disk. A side drain was spin-welded to the drum to drain the dirty water that pooled on the surface. This was the beginning model for summer 2014. |

...

The Chemical Dose Controller was redesigned with (1) an altered constant head tank constructed from Nalgene bottles or a 3” pipe, (2) the float situated inside the LFOM, eliminating the need for an entrance tank, and (3) major headloss elements that run vertically to reduce overall size.

Tests through mass spectrometry have confirmed that chemicals are leaching from the foam, however more testing must be done to determine the composition of the leachate. Designs for the on-the-ground implementation of the foam filter pilot project have been drawn up by AguaClara Engineer, Walker Grimshaw in Honduras. This design includes the set-up for the chemical stock tanks, designs for managing backwash and finished water, and the possible addition of a grit chamber.

The lever arm used for plunging the foam was redesigned with a rigid connection to the base of the filter support. This rigid connection eliminates large movement in the z-direction and the need for guidance by the barrel lid on the 55-gallon drum. The open-top design allows for integration of the new CDC/LFOM design: influent raw water pours out of the LFOM and directly into the filter body.

| Section | ||||||

|---|---|---|---|---|---|---|

| Section | ||||||

*PPI stands for pores per inch, which is a linear measurement of foam pore size. A larger pore size number (i.e.60 ppi) corresponds to a smaller pore size.

|