| Include Page | ||||

|---|---|---|---|---|

|

| Include Page | ||||

|---|---|---|---|---|

|

Laminar Pipe Flow

Created using ANSYS 13.0

...

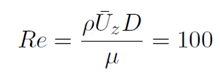

Consider fluid flowing through a circular pipe of constant radius as illustrated above. The figure is not to scale. The pipe diameter D = 0.2 m and length L = 8 m. The inlet velocity Ūz = 1 m /s. Consider the inlet velocity to be constant over the inlet cross-section and equal to 1 m/s. The fluid exhausts into the ambient atmosphere which is at a pressure of 1 pressure at the pipe outlet is 1 atm. Take density ρ = 1 kg/ m3 and coefficient of viscosity µ = 2 x 10-3 kg/(msm s). The Reynolds number Re based on the pipe diameter is

where Ūz is the average velocity at the inlet, which is 1 m/s in this case. These parameters have been chosen to get a desired Reynolds number of 100 and don't correspond to any real fluid.

Solve this problem numerically using ANSYS FLUENT via ANSYS Workbench. Plot the velocity and pressure variation within the pipe. Validate your results.Note: The values used for the inlet velocity and flow properties are chosen for convenience rather than to reflect reality. The key parameter value to focus on is the Reynolds numberVerify your results.

Go to Step 1: Pre-Analysis & Start-Up

...

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!