...

The blade is made out of an orthotropic composite material, it has a varying thickness and it also has a spar inside the blade for structural rigidity. These specs, which are important for the FEA simulation, are described in more details in Part 2 of the tutorial.

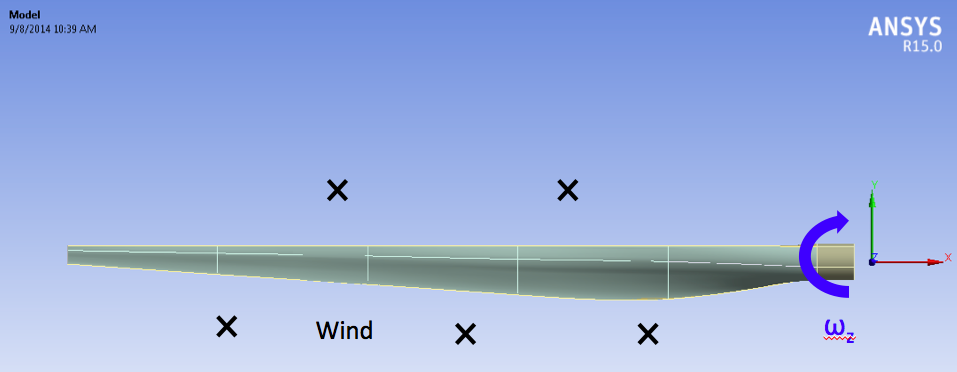

The turbulent wind is coming from flows towards the negative z-direction at (into the page on the above diagram) at 12 m/s which is a typical rated wind speed for a turbine this size. This incoming flow makes the blade rotate at an angular velocity of -2.22 rad/s about the z-axis (the blade is thus spinning clockwise when looking at it from the front, like most real wind turbines). The blade root is offset from the axis of rotation by 1 meter to make it more representative of an actual turbine where the blades would connect to the hub. Note that the blade root is offset from the axis of rotation by 1 meter to represent the blade being connected to a hub.

...

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!