| Include Page | ||||

|---|---|---|---|---|

|

| Include Page | ||||

|---|---|---|---|---|

|

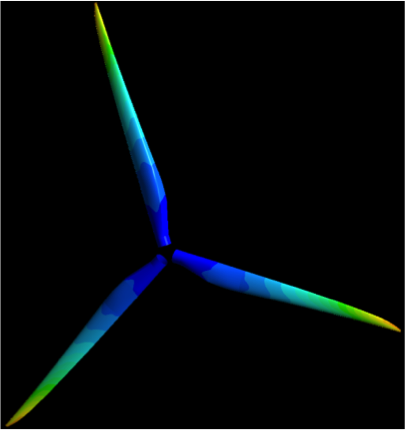

Wind Turbine Blade FSI (Part 2)

Created using ANSYS 1415.50

| Info |

|---|

To access Part 1 of the tutorial, click here. |

...

Overview

Option #1:

This tutorial considers the deformation due to aerodynamic loading of a wind turbine blade by performing a steady-state 1-way FSI (Fluid-Structure Interaction) analysis. Part 1 of the tutorial uses ANSYS Fluent to develop the aerodynamics loading on the blade. In part 2, the pressures on the wetted areas of the blade are passed as pressure load to ANSYS Mechanical which performs the Computational Structural Mechanics (CSM) to determine stresses and deformations on the blade.

The blade is 42.3 meters long and starts with a cylindrical shape at the root and then transitions to the airfoils S818, S825 and S826 for the root, body and tip, respectively. This blade also has pitch to vary as a function of radius, giving it a twist and the pitch angle at the blade tip is 4 degrees. This blade was created to be similar in size to a GE 1.5XLE turbine. For more information on the dimension characteristics of this blade, please see this M.Eng report (note that model in the present tutorial has an additional 2 meter cylindrical extension at the root to make it more realistic).

The blade is made out of an orthotropic composite material, it has a varying thickness and it also has a spar inside the blade for structural rigidity. These specs, which are important for the FEA simulation, are described in more details in Part 2 of the tutorial.

The wind is coming from the z-direction at 12 m/s which is a typical rated wind speed for a turbine this size. This incoming flow makes the blade rotate at an angular velocity of -2.22 rad/s about the z-axis (the blade is thus spinning clockwise when looking at it from the front, like most real wind turbines). The blade root is offset from the axis of rotation by 1 meter to make it more represenetative of an actual turbine where the blades would connect to the hub. Note that the blade root is offset from the axis of rotation by 1 meter to represent the blade being connected to a hub.

| Note |

|---|

Under Construction |

In Part 2

This section involves the solid mechanics aspects of this wind turbine blade tutorial. The pressures load found using Fluent in Part 1 are imported in Mechanical and the stresses and deformations on the blade are subsequently determined.

27m long with a rotational angular velocity of 2.43 rad/s. The upstream wind speed (or should we say the free stream velocity?) is 8 m/s. The blade is made out of an orthotropic composite material with the following properties: (Should we include all this info here or only in Part 2?)

Density Density (kg/m^3) | 1550 |

|---|---|

Young's Modulus-X (Pa) | 1.1375E+11 |

Young's Modulus-Y (Pa) | 7.583E+09 |

Young's Modulus-Z (Pa) | 7.583E+09 |

Poisson's Ratio-XY | 0.32 |

Poisson's Ratio-YZ | 0.37 |

Poisson's Ratio-XZ | 0.35 |

Shear Modulus-XY (Pa) | 5.446E+09 |

Shear Modulus-YZ (Pa) | 2.964E+09 |

Shear Modulus-XZ (Pa) | 2.964E+09 |

...

Option #2 (almost exact copy of Edwin's text):

This steady-state 1-way FSI (Fluid-Structure Interaction analysis that uses Fluent+Mechanical) example considers the deformation due to aerodynamic loading of a wind turbine blade. The blade is 27m long with a rotational velocity of 2.43 rad/s. The upstream wind speed is 8 m/s. The Computational Fluid Dynamics (CFD) is performed using ANSYS Fluent to develop the aerodynamic loading on the blade (Part 1 of this tutorial). The pressure on the wetted areas of the blades are the passed as a pressure load in ANSYS Mechanical which performs the Computational Structural Mechanics (CSM) to determine stresses and deformations on the blade (Part 2 of this tutorial).

Material??

| Note |

|---|

Under Construction |

In Part 2

This section involves the solid mechanics aspects of this wind turbine blade tutorial. The pressures load found using Fluent in Part 1 are imported in Mechanical and the stresses and deformations on the blade are subsequently determined.

| Note |

|---|

Under Construction |

Go to Step 1: Pre-Analysis & Start-Up

...

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!