| Include Page | ||||

|---|---|---|---|---|

|

| Include Page | ||||

|---|---|---|---|---|

|

Wind Turbine Blade FSI (Part 1)

Created using ANSYS 14.5

Problem Specification

Overview

Option #1:

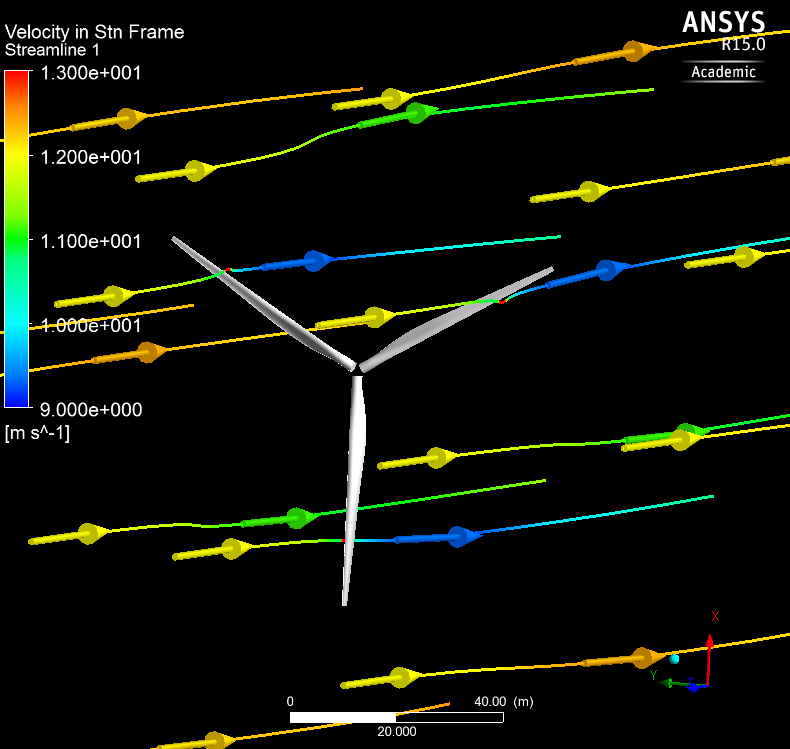

This tutorial considers the deformation due to aerodynamic loading of a wind turbine blade by performing a steady-state 1-way FSI (Fluid-Structure Interaction) analysis. Part 1 of the tutorial uses ANSYS Fluent to develop the aerodynamics loading on the blade. In part 2, the pressures on the wetted areas of the blade are passed as pressure load to ANSYS Mechanical which performs the Computational Structural Mechanics (CSM) to determine stresses and deformations on the blade.

The blade is 27m long with a rotational angular velocity of 2.43 rad/s. The upstream wind speed (or should we say the free stream velocity?) is 8 m/s. The blade is made out of an orthotropic composite material with the following properties: (Should we include all this info here or only in Part 2?)

Density (kg/m^3) | 1550 |

|---|---|

Young's Modulus-X (Pa) | 1.1375E+11 |

Young's Modulus-Y (Pa) | 7.583E+09 |

Young's Modulus-Z (Pa) | 7.583E+09 |

Poisson's Ratio-XY | 0.32 |

Poisson's Ratio-YZ | 0.37 |

Poisson's Ratio-XZ | 0.35 |

Shear Modulus-XY (Pa) | 5.446E+09 |

Shear Modulus-YZ (Pa) | 2.964E+09 |

Shear Modulus-XZ (Pa) | 2.964E+09 |

*Include more details on the boundary conditions?

Option #2 (almost exact copy of Edwin's text):

This steady-state 1-way FSI (Fluid-Structure Interaction analysis that uses Fluent+Mechanical) example considers the deformation due to aerodynamic loading of a wind turbine blade. The blade is 27m long with a rotational velocity of 2.43 rad/s. The upstream wind speed is 8 m/s. The Computational Fluid Dynamics (CFD) is performed using ANSYS Fluent to develop the aerodynamic loading on the blade (Part 1 of this tutorial). The pressure on the wetted areas of the blades are the passed as a pressure load in ANSYS Mechanical which performs the Computational Structural Mechanics (CSM) to determine stresses and deformations on the blade (Part 2 of this tutorial).

Material??

| Note |

|---|

Under Construction |

Part 1

In this section of the tutorial, the blade geometry is imported, a mesh is created around the blade and Fluent is then used to find the aerodynamics loading on the blade.

| Note |

|---|

Under Construction |

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!