| Include Page | ||||

|---|---|---|---|---|

|

| Include Page | ||||

|---|---|---|---|---|

|

Verification and Validation

Now that we have our results, it is important that we check to see that our computational simulation is accurate. One possible way of accomplishing this task is comparing to the pre-calculations, as we did in the results section. Another way to check our results is by refining the mesh further. The smaller the elements in the mesh, the more accurate our simulation will be, but the simulation will take longer. To refine the mesh, look to the outline tree and click Mesh > Body Sizing Change the element sizing to .05 (half the size of the mesh we originally tried). The new mesh looks like this . It has twice as many elements as the original.

...

The ARAMIS works in a similar fashion to a finite element analysis. First the part to be loaded is painted with a speckled pattern, and a picture is taken at the zero load state. ARAMIS maps facets, essentially two dimensional elements, to the speckled pattern. Each facet contains a unique pattern of speckles within it, and ARAMIS tracks the movements of each of these patterns while the part is being loaded. The facet size can be adjusted, just as the element size in FEA software can. Multiple pictures are taken as the load is applied to the part, and at each stage the ARAMIS calculates strain fields in the X and Y directions, along with other results such as Von Mises strain and shear angle. The results are mapped to the face of the part as contours.

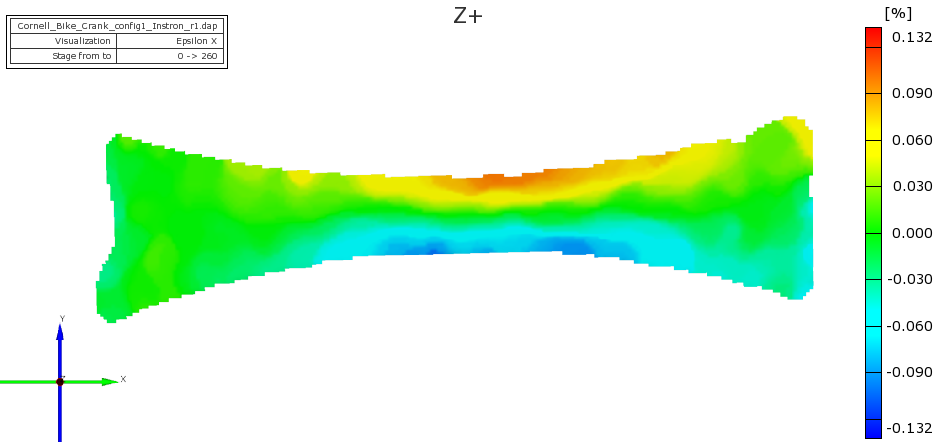

ARAMIS was used to obtain the X and Y strain fields for a bike crank made from Al 6061 T6, and an ANSYS model of the same geometry and loading conditions was created. The results of the strain fields output are shown below:

ARAMIS X-Strain Field:

ANSYS X-Strain Field:

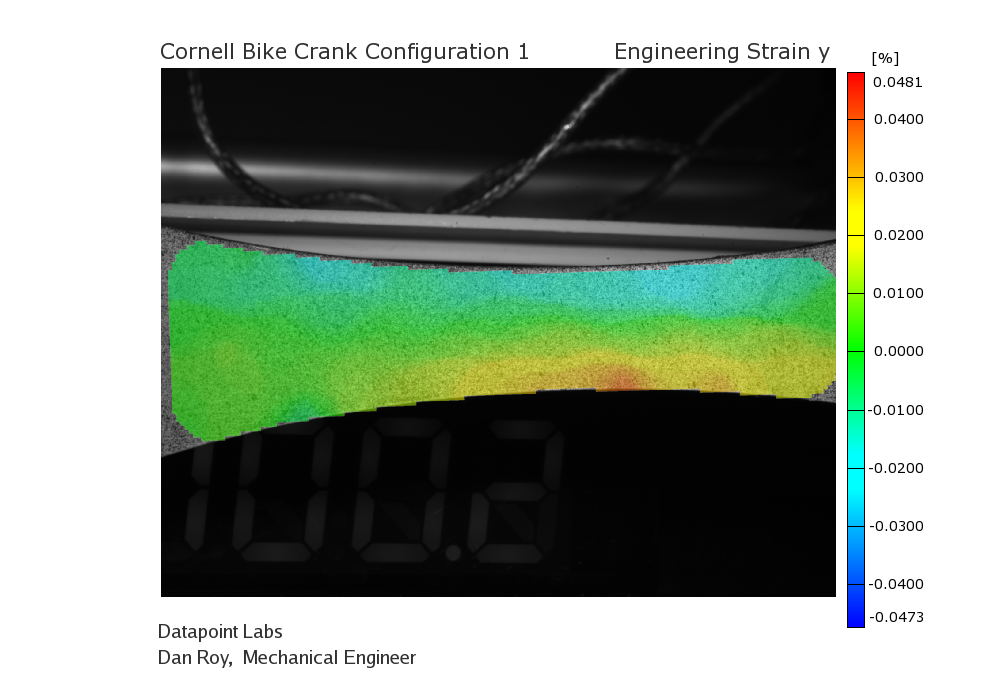

ARAMIS Y-Strain Field:

...

ANSYS accurately predicts the regions and magnitudes of the strain concentrations in the direction with the greatest strains. It also accurately reports X-strain gauge values. The X-direction is also of more interest because it has higher strains. Even though the Y-direction did not have as close of a correlation, the discrepancy is believed to be due to the material properties of the bicycle crank.

For more details on validation using digital image correlation, see Validation of ANSYS Workbench with DIC.doc.

We're Done!

Click here to go to all ANSYS Learning Modules

See and rate the complete Learning Module

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!