| Include Page | ||||

|---|---|---|---|---|

|

| Include Page | ||||

|---|---|---|---|---|

|

Verification & Validation

| Info |

|---|

MAE 3240/4230/5230 Spring 2020: Please read through this section for your understanding. You DO NOT need to complete this section in ANSYS for the homework (feel free to give it a try though if you are curious). MAE 3240 students need to complete the next section: Part II, Flat Plate Convection |

| Panel |

|---|

Author: John Singleton and Rajesh Bhaskaran, Cornell University Problem Specification |

| Note | ||

|---|---|---|

| ||

This page of this tutorial is currently under construction. Please check back soon. |

Step 7: Verification & Validation

It is very important that you take the time to check the validity of your solution. This section leads you through some of the steps you can take to validate your solution.

Refine Mesh

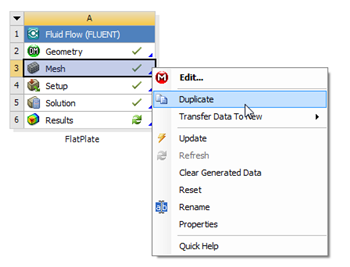

Let's repeat the solution on a finer mesh. For the finer mesh, we will use increase the total number of elements(cells) by a factor of twofour. In order to accomplish this, we double the number of divisions on each section. Instead of modifying the project that was just created, we will duplicate it and modify the duplicate. In the Workbench Project Page right click on Mesh then click Duplicate as shown below.

| newwindow | ||||

|---|---|---|---|---|

| ||||

https://confluence.cornell.edu/download/attachments/85624049/DupMesh_Full.png |

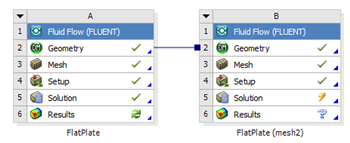

Rename the duplicate project to Laminar Pipe Flow FlatPlate (mesh 2). You should have the following two projects in your Workbench Project Page.

Next, double click on the Mesh cell of the Laminar Pipe Flow FlatPlate (mesh 2) project. A new ANSYS Mesher window will open. Under Outline, expand Mesh and click on Edge Sizing, as shown below.

Under Details of "Edge Sizing", enter 10 100 for Number of Divisions, as shown below.

newwindow

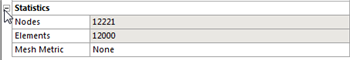

https://confluence.cornell.edu/download/attachments/85624049/10DivSet_Full.pngThe new mesh should now have 1000 12000 elements (10 100 x 1001200). A quick glance of the mesh statistics reveals that there is indeed 1000 12000 elements.

| newwindow | ||||

|---|---|---|---|---|

| ||||

https://confluence.cornell.edu/download/attachments/ |

...

141036304/ |

...

MeshStat1_Full.png |

Compute the Solution

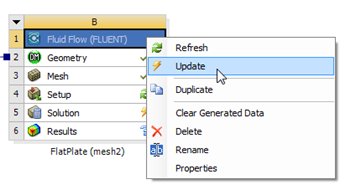

Close the ANSYS Mesher to go back to the Workbench Project Page. Under Laminar Pipe Flow FlatPlate (mesh 2), right click on Fluid Flow (FLUENT) and click on Update, as shown below.

newwindow

Now, wait a few minutes for FLUENT to obtain the solution for the refined mesh. After FLUENT obtains the solution, save your project.

...

Convergence

In order to launch FLUENT double click on the Solution of the "Laminar Pipe Flow FlatPlate (mesh 2)" project in the Workbench Project Page. After, FLUENT launches (Click) Plots > XY Plot > SetUp... as shown in the image below.

For this graph, the y axis of the graph will have to be set to the y axis of the pipe (radial direction). To plot the position variable on the y axis of the graph, uncheck Position on X Axis under Options and choose Position on Y Axis instead. To make the position variable the radial distance from the centerline, under Plot Direction, change X to 0 and Y to 1. To plot the axial velocity on the x axis of the graph, select Velocity... for the first box underneath X Axis Function, and select Axial Velocity for the second box. Next, select outlet, which is located under Surfaces. Then, uncheck the Write to File check box under Options, so the graph will plot. Now, your Solution XY Plot menu should look exactly like the following image.

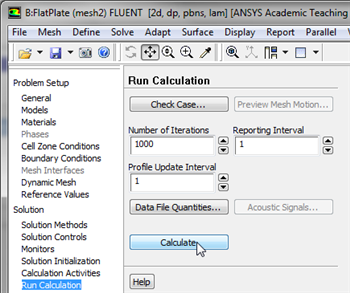

The new mesh has significantly more cells, thus it is likely that the solution did not converge to the tolerances we have previously set. Therefore, we will iterate the solution further, to make sure that the solution converges. In order to do so click on Run Calculation, set Number of Iterations to 1000 and click Calculate, as shown below.

| newwindow | ||||

|---|---|---|---|---|

| ||||

https://confluence.cornell.edu/download/attachments/ |

...

141036304/ |

...

runcalc2_Full.png |

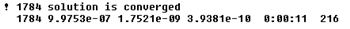

Once you rerun the calculation, you will quickly see that the solution did not converge for the finer mesh within 1000 iterations. The solution should converge by the 1784th iteration as shown below.

Outlet Velocity Profile

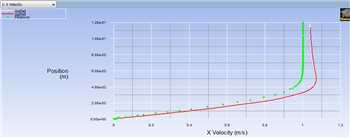

Now, the variation of the x component of the velocity will be plotted with the results of the original mesh to determine whether the solution is mesh converged. Set up a plot for the variation of the x component of the velocity along the outlet as was done in the solution section. Then load the XVelOutlet.xy file into the plot and generate the plot. You should obtain the following image.

Since we would like to see how the results compare to the courser mesh and the theoretical solution, we will load the profile.xy file, which was created in the previous step. In order to do so, click Load File... in the Solution XY Plot menu, then select the profile.xy file. Click OK, then click Plot in the Solution XY Plot menu. You should then obtain the following plot.

| newwindow | ||||

|---|---|---|---|---|

| ||||

https://confluence.cornell.edu/download/attachments/ |

...

141036304/ |

...

VelFinal_Full.png |

...

As one can see from the image above, the numerical solution does not vary much at all between the two meshes. Thus, it has been confirmed that the solution is mesh converged.

Go To Step 8: Flat Plate Convection

Go to all FLUENT Learning Modules

Further Verification

The plot below shows the results of a further refined mesh ( 20 radial x 100 axial ) and the theoretical results.

newwindow

https://confluence.cornell.edu/download/attachments/85624049/PlotL_Full.png Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!