Step 9: Validate the results

...

Main Menu > General Postproc > List Results > Reaction Solu

Select All struc forc F for Item to be listed and click OK.

The total reaction force in the x-direction is -7000 N.

...

Main Menu > Preprocessor > Meshing > Mesh Tool

Select Clear under Mesh: and Pick All in the pick menu. The mesh is deleted.

Set the overall element size level under SmartSize to 4 by dragging the slider to the left. Click on Mesh and Pick All.

In the Output window, check how many elements are contained in this mesh? Your new mesh should have 320 quadrilateral elements.

...

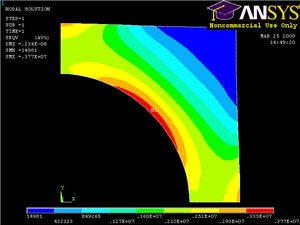

Main Menu > General Postproc > Plot results > Contour Plot > Nodal Solu

Select Nodal Solution > Stress > von Mises stress and click OK

Compare this with the von Mises contours for the previous mesh:

...

The two results compare well with the finer mesh contours being smoother as expected. Compare the maximum stress and displacement values:

. | Coarser Mesh | Finer Mesh |

DMX | 0.232e-8m | 0.234e-8m |

SMX | 3.64MPa | 3.77MPa |

...

Utility Menu > File > Exit

Select Save Everything and click OK.

Reference

| Anchor | ||||

|---|---|---|---|---|

|

...

Sign-up for free online course on ANSYS simulations!

Sign-up for free online course on ANSYS simulations!